Introduce:

In the manufacturing world, fasteners such as bolts, screws, washers, and universal fasteners play a vital role in holding structures together. While their importance is undeniable, the unsung heroes responsible for their consistent quality are fastener molds. As technology advances, fastener molds have evolved exponentially, revolutionizing the manufacturing process and improving overall efficiency. This blog takes an in-depth look at revolutionary bolt screw dies, washer screw dies, and universal fastener dies to explore how these innovations are redefining precision, durability, and versatility in the world of fastening solutions.

Release Accuracy: Bolt Screw Mold:

Precision is a quintessential element of fastener manufacturing, ensuring compatibility and reliability. Bolt and screw dies have become the epitome of precision, guaranteeing consistently accurate results. The combination of cutting-edge technologies allows for tighter tolerances, reducing deviations and eliminating the possibility of fastener failure due to mold failure. Manufacturers can now produce bolts and screws with consistently accurate dimensions, thread dimensions and head shapes, allowing for seamless integration into a variety of applications.

Enhanced Durability: Washer Screw Mold:

The importance of washers in distributing loads and minimizing the risk of damage cannot be overstated. To this end, significant advancements have been made in washer screw moulds, resulting in highly durable and efficient gaskets. These molds use reinforced materials and innovative design techniques to improve strength, resistance to deformation and overall performance. In addition, the ability to produce uniform, defect-free gasket screws satisfies industries that require superior reliability and service life.

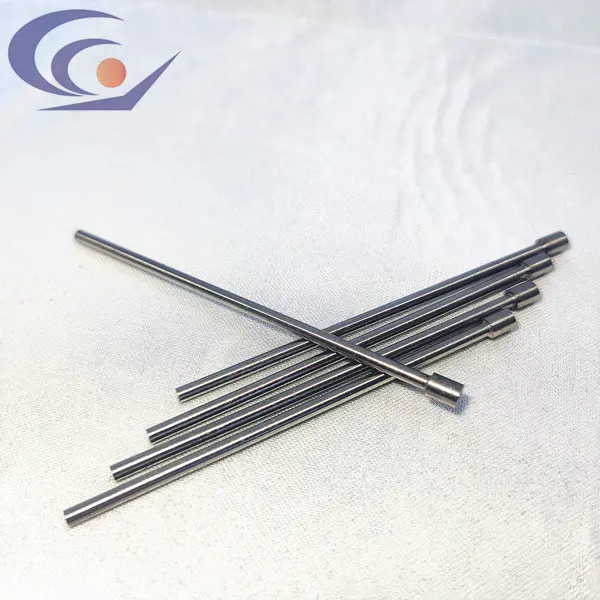

Versatility Redefined: Universal Fastener Molds:

In a world where customization and adaptability have become critical, the emergence of universal fastener molds paves the way for efficient and cost-effective manufacturing processes. These molds can produce not only specialized fasteners, but also multi-purpose fasteners that can be adapted to a variety of applications. Universal fastener molds enable manufacturers to meet the diverse needs of customers, eliminating the need for multiple specialized molds and simplifying production.

The intersection of tradition and innovation:

While fastener mold technology continues to make significant advances, it is critical to recognize the traditional and time-tested principles that still define manufacturing. The expertise of skilled mold designers and engineers is the backbone of innovation. This seamless blend of traditional knowledge and cutting-edge technology creates fastener molds that embody the best of both worlds.

In conclusion:

Advances in bolt screw molds, washer screw molds, and universal fastener molds have undoubtedly changed the fastener manufacturing landscape. These groundbreaking innovations deliver unparalleled precision, durability and versatility, revolutionizing the way fasteners are produced and used. As technology continues to advance, it is exciting to look ahead to the improvements that fastener molds will bring, further optimizing manufacturing processes and enhancing the durability and reliability of fasteners worldwide.

Post time: Oct-09-2023